Basic principles and features:

Optical fiber transmission laser welding machine is a high-energy laser beam coupled into the optical fiber, long-distance transmission, collimated by the collimating lens for parallel light, and then focus on the workpiece to implement a welding laser welding equipment. For welding difficult to access the site, the implementation of non-contact transmission of flexible transmission, with greater flexibility. Optical fiber transmission laser welding machine laser beam can be achieved on the time and energy of the beam, simultaneous multi-beam processing for more sophisticated welding provided the conditions.

Model Description: Optical fiber transmission laser welding machine, also known as: optical fiber welding, fiber laser welding, fiber laser welding machine. Using the leading high-power optical fiber transmission technology, the performance of the equipment is similar to that of similar products in the world, and the multi-station processing can be achieved by splitting the light. The optical fiber imported from Germany has the advantages of stable energy, large depth-to-diameter ratio and low fiber loss. Series of optical fiber transmission laser welding machine with good beam quality, fine spots and other characteristics; and optional robot, crane, CCD camera surveillance system for special welding, precision alignment and welding real-time monitoring.

Industry applications and applicable materials: Can be widely used in molds, power batteries, sheet metal processing, telecommunications, steel, microelectronic components, precision parts, high-end digital components, medical equipment and other industries. Weldable Material: Carbon Steel, Plain Alloy Steel, Stainless Steel, Laser Welding Between Different Steels, Stainless Steel - Mild Steel, 416 Stainless Steel-310 Stainless Steel, 347 Stainless Steel -ASTALLY Nickel Alloy, Nickel Electrode - Cold Forged Steel, Copper- Nickel , Nickel - titanium, copper - titanium, titanium - molybdenum, brass - copper, low carbon steel - copper and other dissimilar metals.

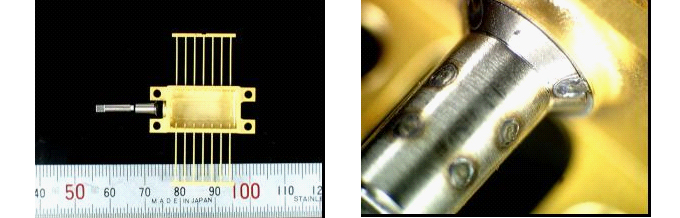

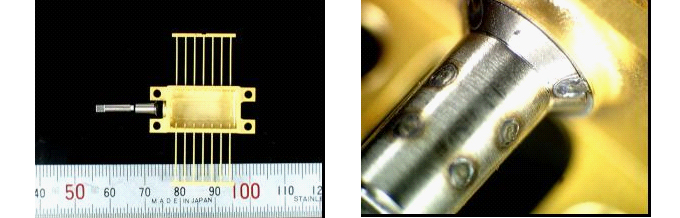

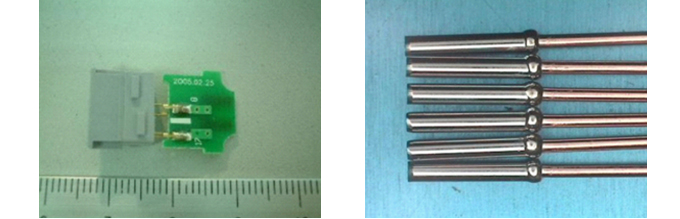

1) butterfly optical communication module welding

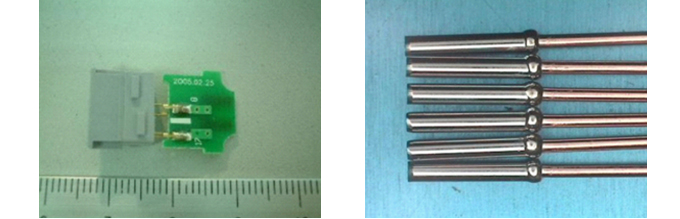

2) enameled wire welding

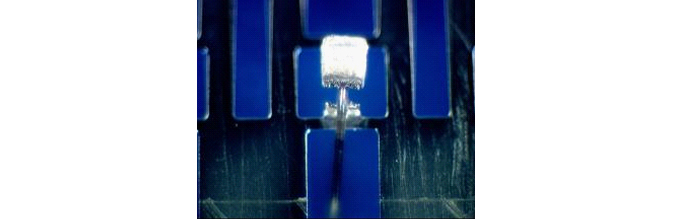

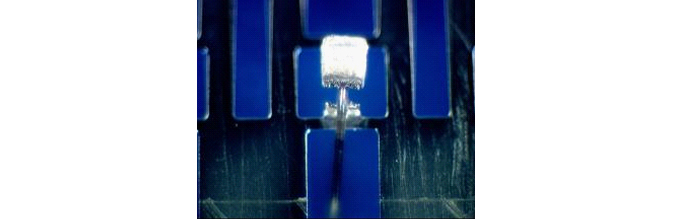

3) positive and negative lithium battery welding

4) laser soldering

5)Wire welding

6) tantalum acid capacitor welding

Technical Parameters

1. Energy closed-loop negative feedback control to ensure the stability of welding quality

The principle of energy closed-loop negative feedback control is to add a laser energy detection device at the optical end of the optical path of the laser. The detection probe detects the size of the laser energy in real time and converts it into an electrical signal. The signal is fed back to the control system in real time, The theoretical laser energy is compared to form a closed-loop negative feedback control system, and then real-time control of the laser power system current, to achieve accurate control of laser energy output purposes. Energy closed-loop negative feedback control system Laser welding machine can stabilize the laser energy of each welding spot, to ensure the stability of each welding spot, and automatically detect the energy attenuation caused by the lamp aging. The energy negative feedback technology can make the laser output energy Has a good repeatability, in simple terms, is to ensure that each output laser energy stability, which can effectively reduce the rate of product failure, is the most advanced technology in the world.

2. Automation software and laser perfectly

The laser power supply adopts the all-digital power controller. It adopts CAN bus (which can be simplified to USB bus for low-cost system) and PC to transmit process waveforms such as power waveform. It adopts high-speed synchronization with FPGA control card. Internal use of DSP to achieve all-digital "current inner ring - voltage ring - laser energy outer ring" tricyclic control method, compared with the traditional analog circuit closed-loop control to eliminate drift, zero drift, and to avoid the individual components of the difference And the effects of aging. Internal PLL power supply PLL synchronous arc welding and laser welding voltage waveform, so that the two can be coordinated and maximize efficiency. In addition the power itself built-in human-machine interface module as shown below.

The output waveform can be arbitrarily set according to the welding material and shape. During the welding process of specific workpieces, various parameters of the laser power supply can be set according to the working shape and material. The output power waveform of the laser power supply can be made through a graphical method Set up, and be able to make the various controls needed.

Changing the output waveform of the laser energy, the actual waveform and the set waveform are compared to achieve a more ideal output waveform, which can greatly improve the welding quality. Even some traditional laser welding problems can be solved by changing the laser output waveform.

Compared with the traditional hard-light output system, the laser can realize long-distance welding, increase the freedom of processing, and can process multiple beams at the same time and multiple stations, providing the conditions for more precise welding. By energy splitting or time-splitting, simultaneous welding or time-division welding is possible. Multi-station real-time energy switch, shorten the processing time, the product line and frequent switching of the production line is very suitable.

You can remove the controller from the machine, holding in your hand, through the monitor can detect the laser power (J) and the average output power (W) of the anomaly, you can eliminate the cause of the balance of the laser surface energy loss, increase Dispute balance quality Pulse width is set wider to achieve better welding quality High-speed pulse frequency can achieve high-precision, high-speed welding.

The key components are imported parts abroad, to ensure product quality.

Shenzhen Laser Technology Co., Ltd. is a high-tech enterprise which focuses on laser light source, laser equipment integration and automation equipment. In the field of solid laser research, production technology level is in the leading ranks in Chin...

Shenzhen Laser Technology Co., Ltd. is a high-tech enterprise which focuses on laser light source, laser equipment integration and automation equipment. In the field of solid laser research, production technology level is in the leading ranks in Chin... Frontiers Insight into the industry information, feel TETE changes, through the industry perspective, look at the TETE initiative. As the leader of laser industry, TETE has been committed to the exploration and...

Frontiers Insight into the industry information, feel TETE changes, through the industry perspective, look at the TETE initiative. As the leader of laser industry, TETE has been committed to the exploration and... Chasing the ideal, we all the way to harvest the scenery! Here is a bright sun, let you bathing the warmth of the team, there is a vast fertile soil, let you learn the strength of growth. To emancipate yourself, you can break out of the earth, and finally get up, and your direction is not influenced by...

Chasing the ideal, we all the way to harvest the scenery! Here is a bright sun, let you bathing the warmth of the team, there is a vast fertile soil, let you learn the strength of growth. To emancipate yourself, you can break out of the earth, and finally get up, and your direction is not influenced by...