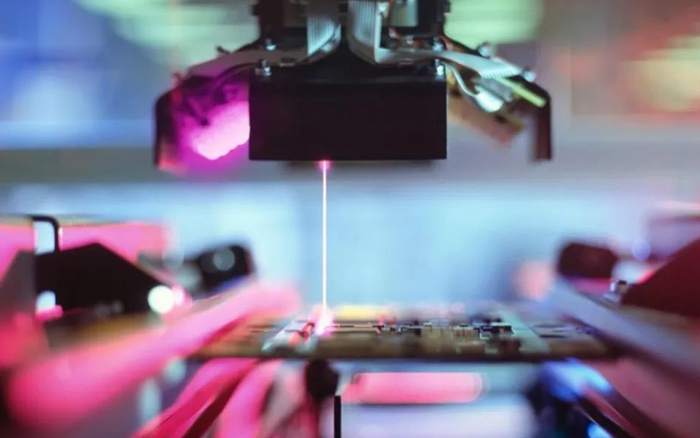

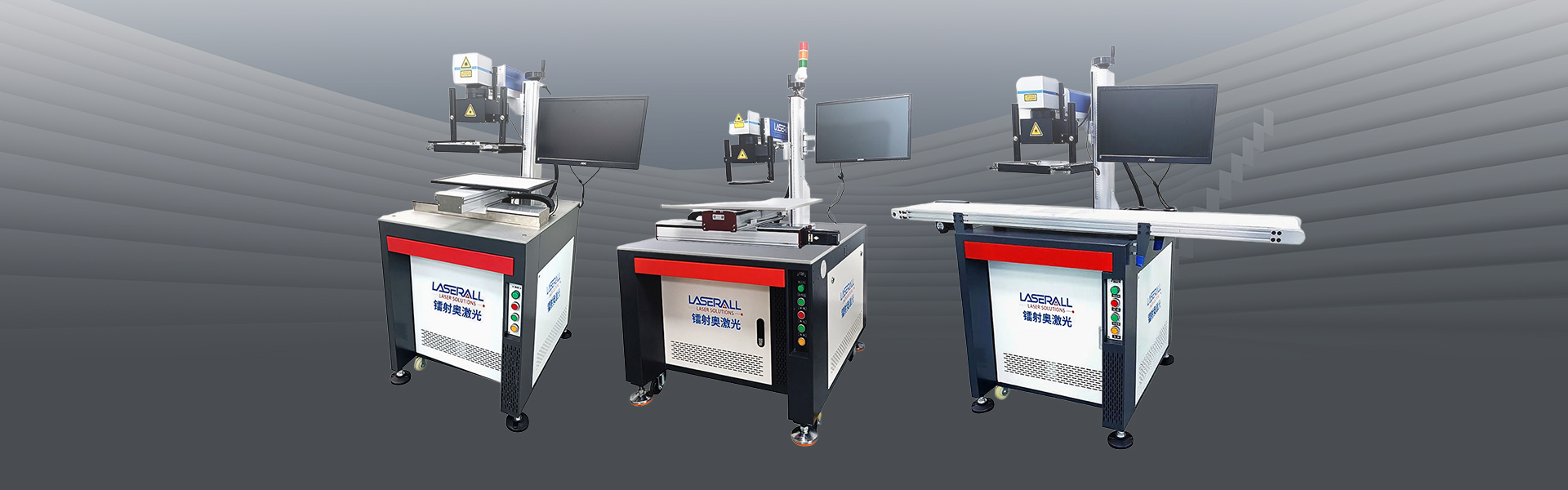

金属中框/边框高精度序列号与二维码打标

High-precision Serial Number & QR Code Marking on Metal Mid-frame/Border

在铝合金、不锈钢等中框内壁进行唯一序列号、二维码永久标识。

Permanent marking of unique serial numbers and QR codes on the inner wall of aluminum alloy, stainless steel mid-frames.

核心技术要点

Core Technical Points

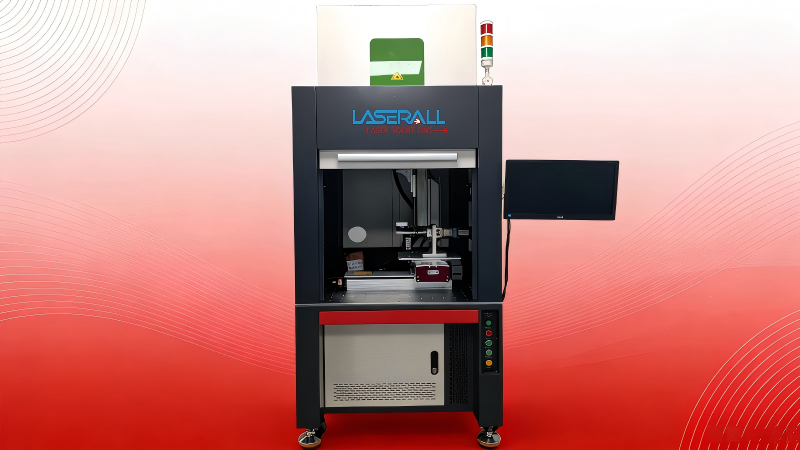

光纤激光器(20-50W),高精度多轴打标系统,小字符优化算法。

Fiber laser (20-50W), high-precision multi-axis marking system, small character optimization algorithm.

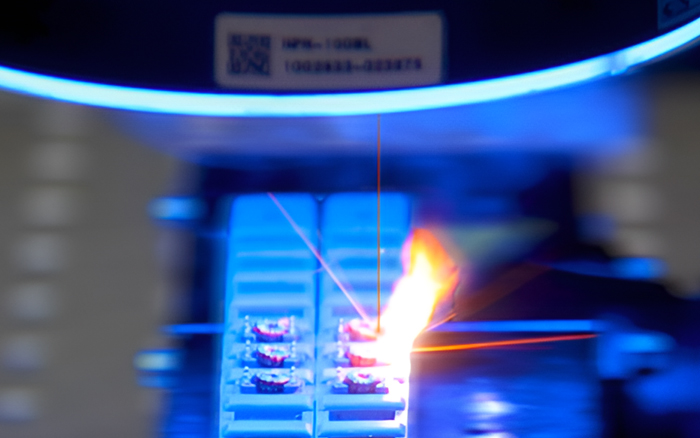

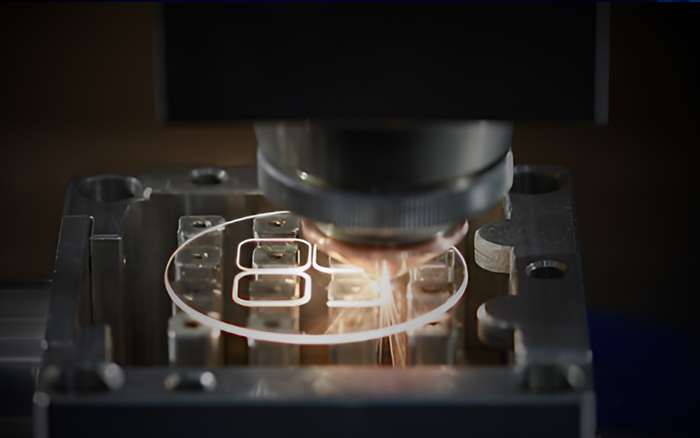

- 永久不可磨灭:标记为深层材料改性,耐刮擦、氧化及汗液腐蚀

- 微空间精密打标:可在宽度<2mm的边框上实现清晰可读的微型二维码

- 适应曲面:配合旋转轴,在弧面中框上保持标记均匀清晰

- Permanent & Indelible: Marking is deep material modification, resistant to scratching, oxidation, and sweat corrosion

- Micro-space Precision Marking: Achieves clear, readable mini QR codes on borders with width <2mm

- Adapts to Curved Surfaces: Maintains uniform, clear marks on curved mid-frames with rotary axis