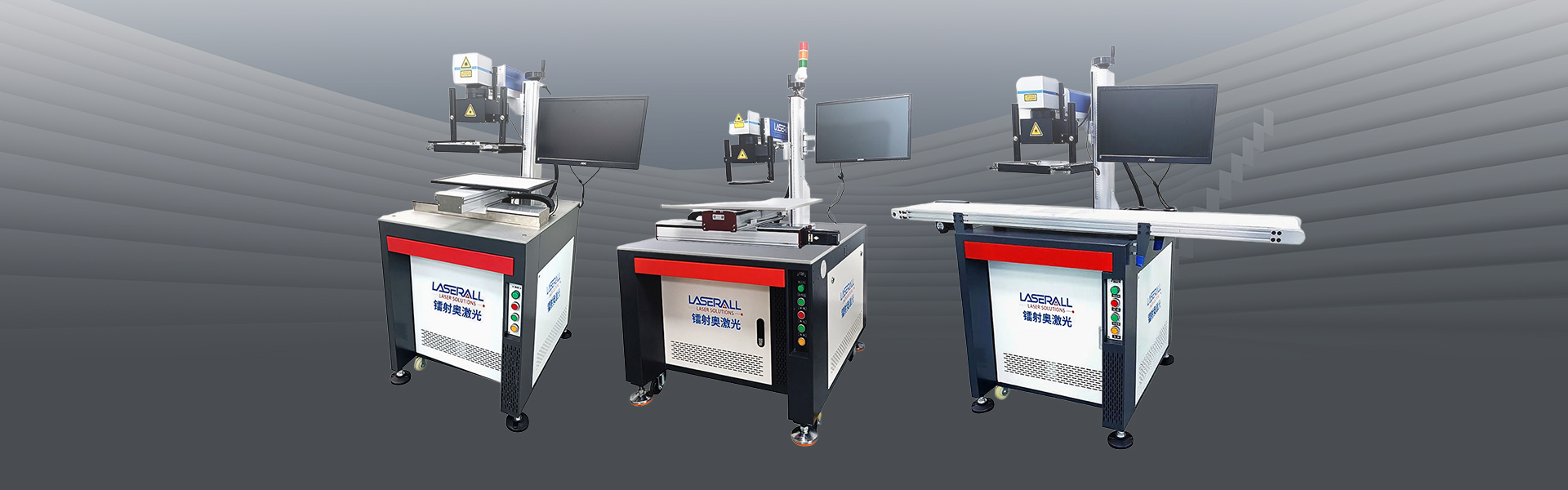

透光按键与装饰面板激光打标

Laser Marking for Transparent Buttons and Panels

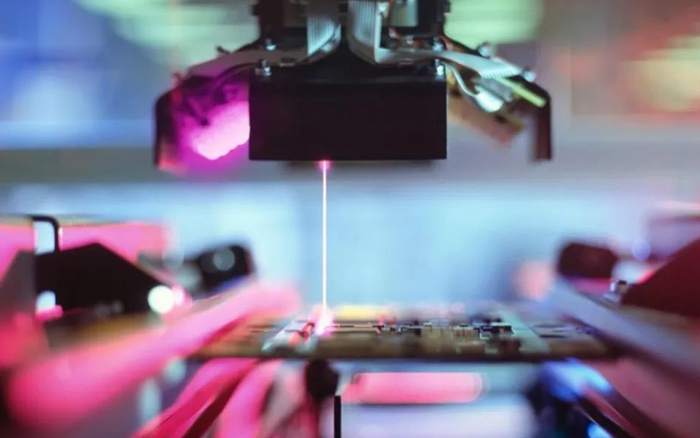

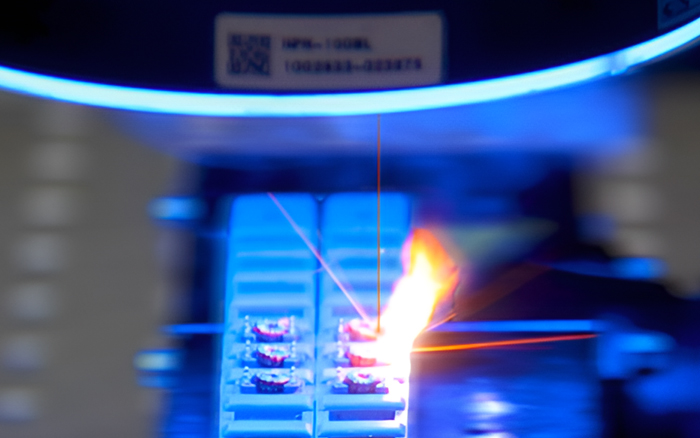

汽车内饰按键背面激光雕刻,实现"点亮清晰、熄灭隐形"的高端背光效果。已通过多家豪华品牌验证。

Backside laser engraving of automotive interior buttons, achieving high-end backlight effect. Verified by multiple luxury brands.

核心技术要点

Core Technical Points

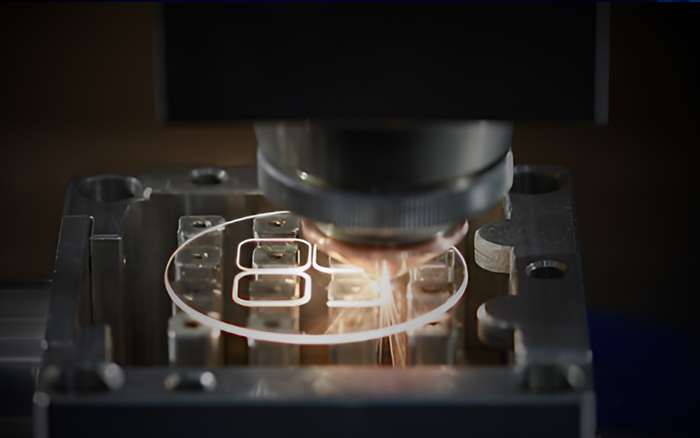

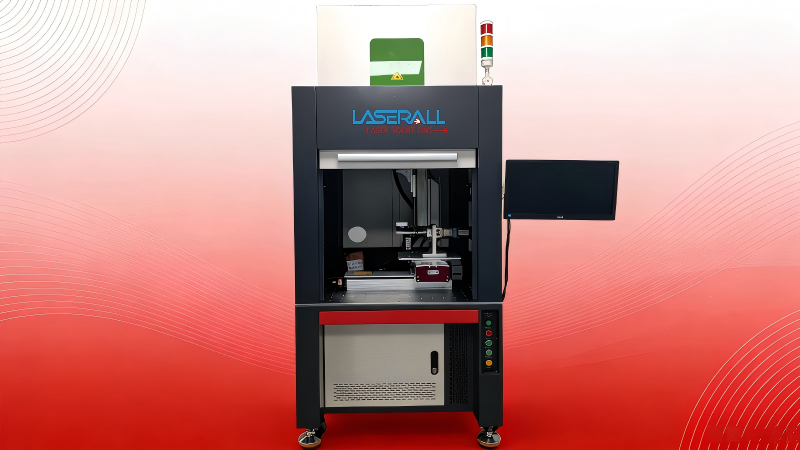

紫外激光/超短脉冲设备,热影响区微米级,确保透光均匀与结构完整。

UV laser/ultrashort pulse equipment with micron-level heat-affected zone ensures uniform light transmission and structural integrity.

- 适用于空调控制区、车窗按键、启动按钮等

- 实现"点亮浮现、熄火隐形"视觉效果

- 满足高端车型精细化与功能性双重要求

- For air conditioning controls, window buttons, start buttons, etc.

- Achieves "visible when lit, invisible when off" effect

- Meets dual requirements for refinement and functionality