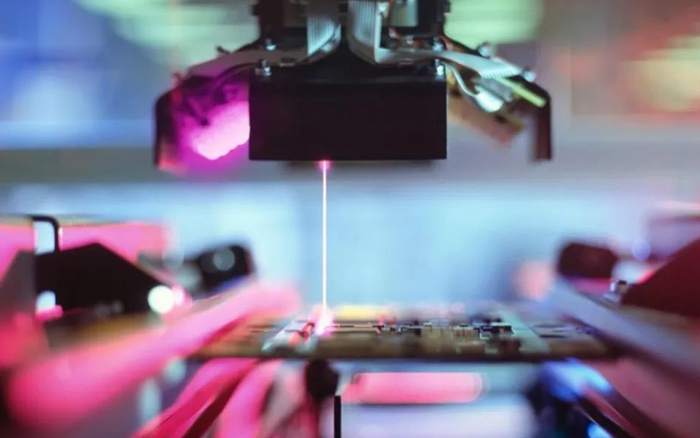

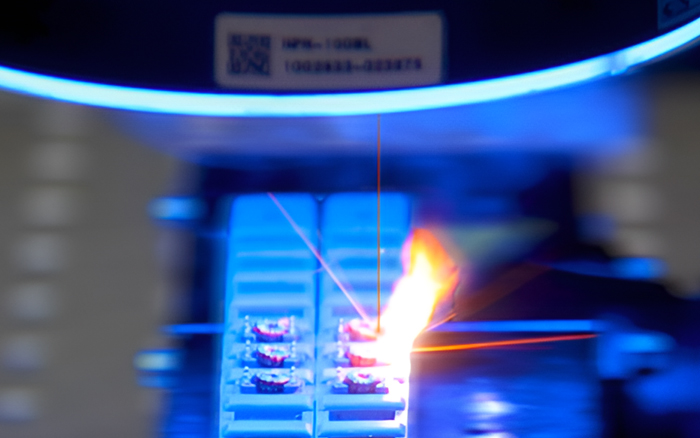

家电控制面板透光按键激光打标

Home Appliance Control Panel Backlit Key Laser Marking

空调、洗衣机等家电PVC/PC控制面板的背光按键字符、图标打标。

Backlit key characters and icon marking on PVC/PC control panels for air conditioners, washing machines, etc.

核心技术要点

Core Technical Points

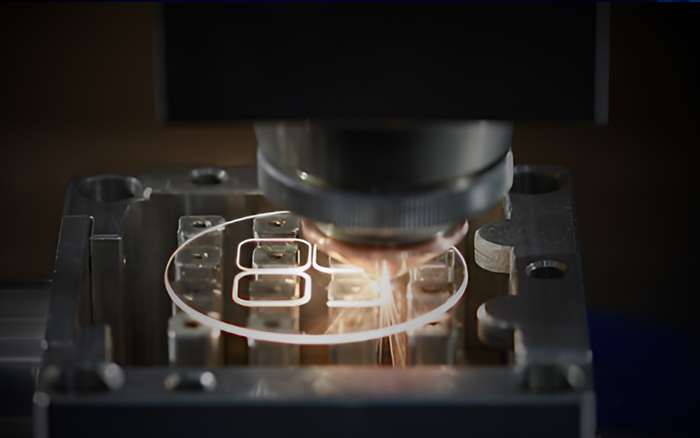

紫外激光器(10-30W),高精度振镜,背面/正面透光打标工艺。

UV laser (10-30W), high-precision galvanometer, back/front light-transmitting marking process.

- “熄屏隐形”效果:实现“点亮清晰、熄灭隐形”的高端视觉效果

- 耐磨损耐清洁:标记耐酒精、清洁剂擦拭,使用寿命长

- 高一致性:适合大规模生产,面板外观一致性极佳

- “Off-screen Invisible” Effect: Achieves high-end visual effect of "clear when lit, invisible when off"

- Wear & Clean Resistant: Marks resistant to alcohol and cleaner wiping, long service life

- High Consistency: Suitable for mass production, excellent panel appearance consistency