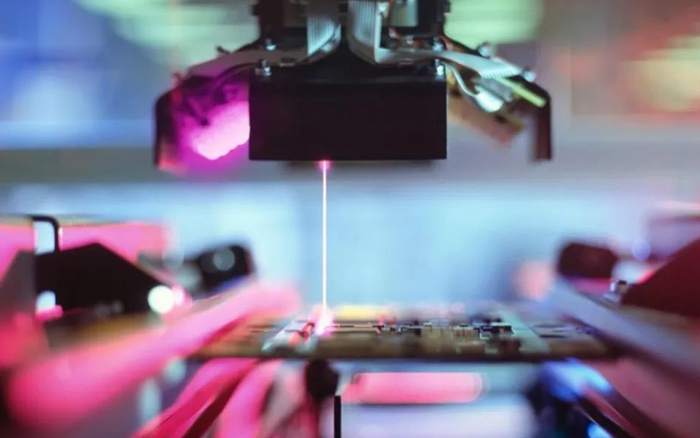

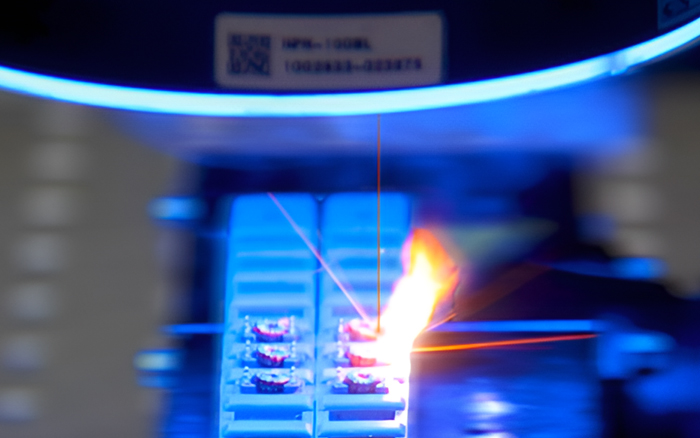

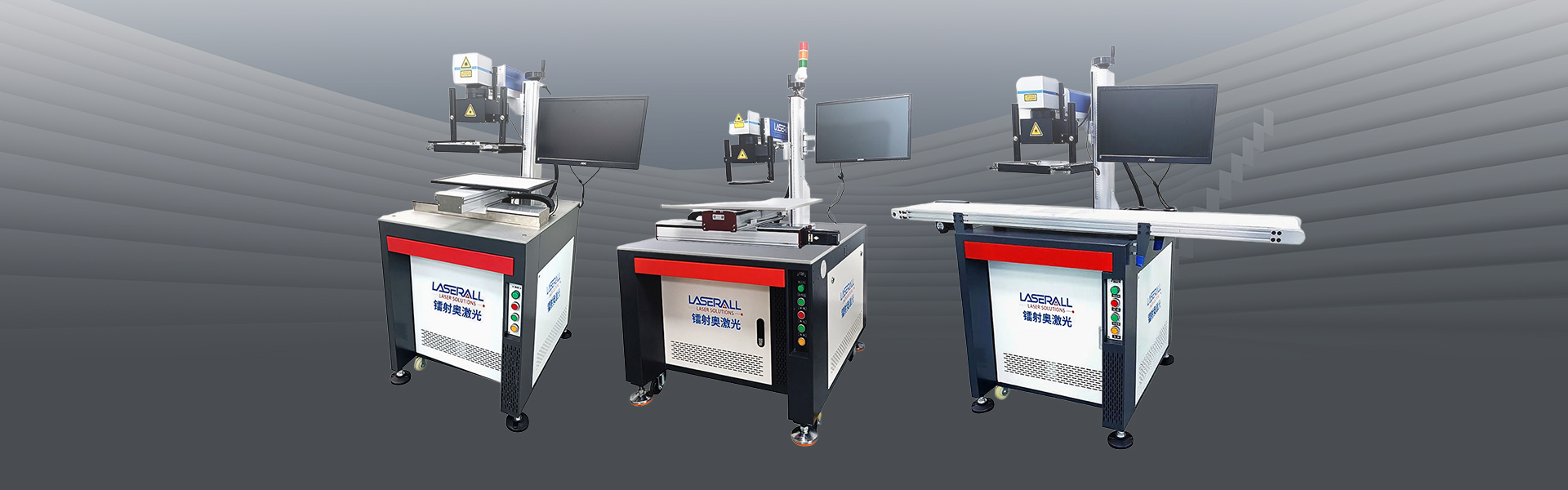

TWS耳机充电仓/耳机柄激光精密打标

TWS Earphone Case/Stem Laser Precision Marking

在塑料、金属耳机表面进行Logo、型号等高精度永久打标。

High-precision permanent marking of logos, model numbers, etc., on plastic and metal earphone surfaces.

核心技术要点

Core Technical Points

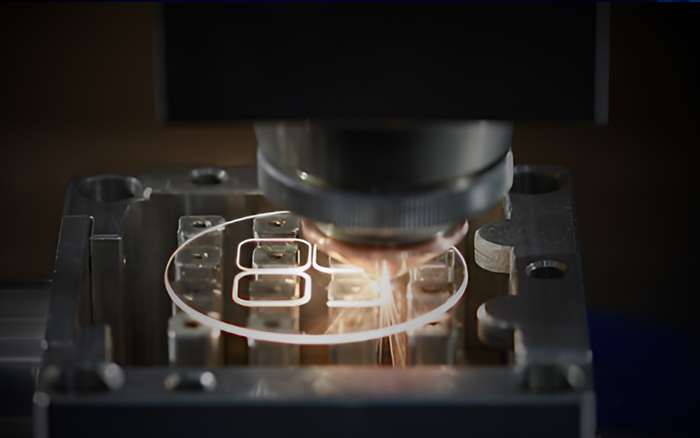

紫外激光器(塑料)/光纤激光器(金属),极小光斑,高精度振镜扫描。

UV laser (plastic) / Fiber laser (metal),极小 spot size, high-precision galvanometer scanning.

- 极细标记:可实现<0.5mm的微小字符和精细Logo,适应紧凑空间

- 高附着力:标记耐磨、耐汗渍、耐酒精擦拭,与产品寿命同步

- 提升高端质感:哑光/亮光对比效果,增强产品辨识度与价值感

- Ultra-fine Marking: Achieves <0.5mm tiny characters and fine logos,适应 compact spaces

- High Adhesion: Marks are wear-resistant, sweat-proof, alcohol-wipe resistant,同步 product lifespan

- Enhances Premium Feel: Matte/gloss contrast effects boost product recognition and perceived value