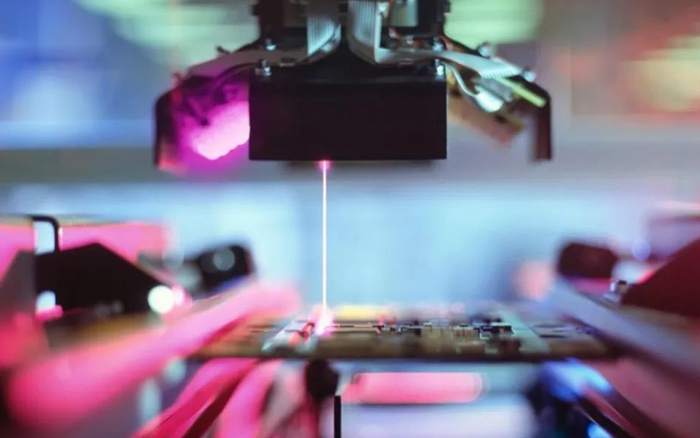

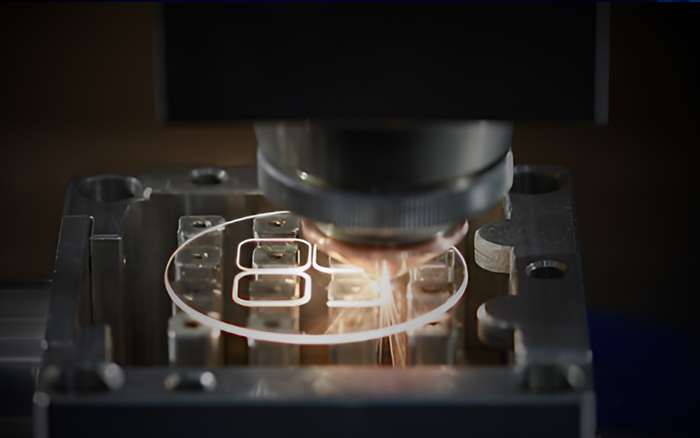

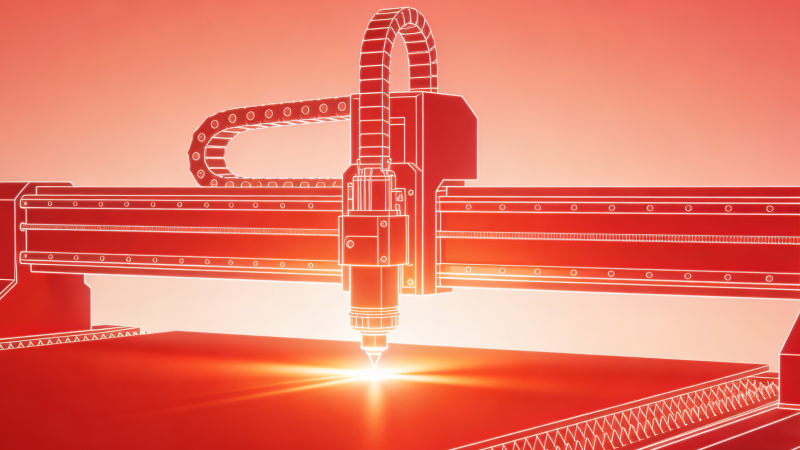

精密陶瓷基板(PCB/陶瓷)切割与钻孔

Precision Ceramic Substrate Cutting & Drilling

切割氮化铝、氧化铝陶瓷基板,为芯片封装提供高精度衬底;钻微通孔。

Cutting aluminum nitride, alumina ceramic substrates for chip packaging; drilling micro-vias.

核心技术要点

Core Technical Points

紫外皮秒激光冷加工技术,高重复频率,光束整形技术。

UV picosecond laser cold processing, high repetition rate, beam shaping technology.

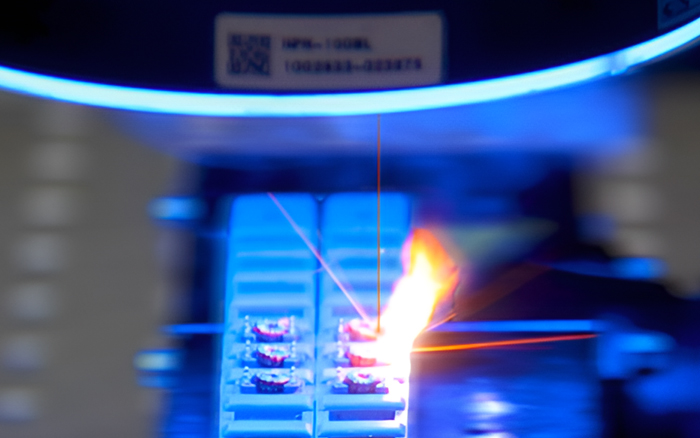

- 无热损伤:切口无熔渣、无微裂纹,保持基板固有强度与绝缘性

- 高精度:切割缝宽<20μm,孔径可小至30-50μm,位置精度±5μm

- 免后续处理:边缘光滑,可直接进入下一道工序

- No Thermal Damage: No slag, no micro-cracks, maintaining substrate strength & insulation

- High Precision: Kerf width <20μm, hole diameter 30-50μm, position accuracy ±5μm

- No Post-processing: Smooth edges, ready for next process step