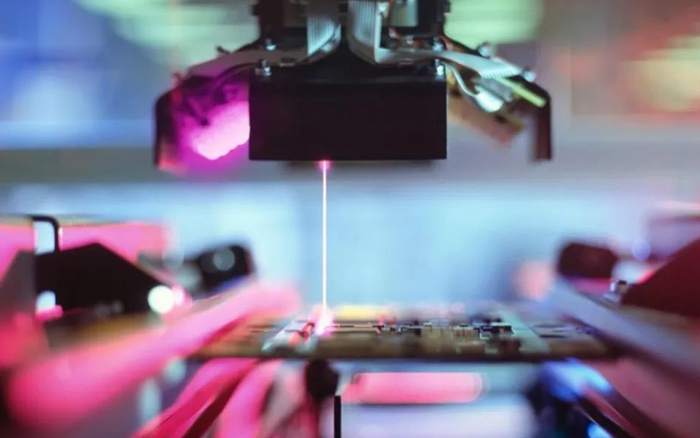

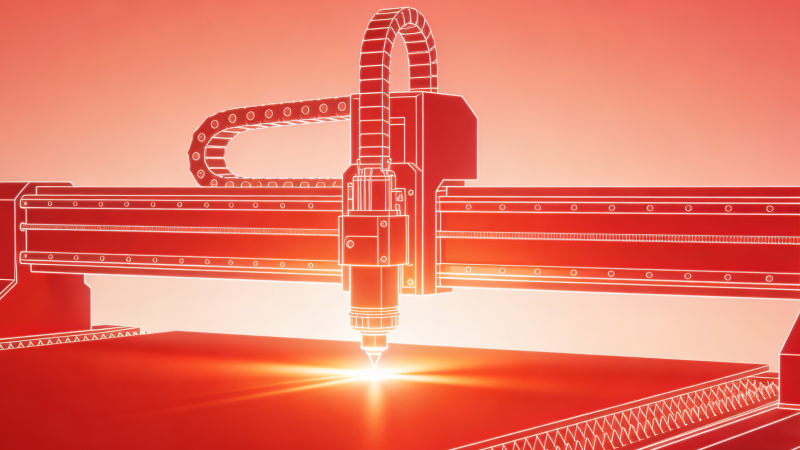

手机/平板盖板玻璃精密切割

Smartphone/Tablet Cover Glass Precision Cutting

智能手机、平板电脑盖板玻璃的异形轮廓切割、听筒孔、按键孔加工。

Contour cutting, receiver holes, and button holes for smartphone and tablet cover glass.

核心技术要点

Core Technical Points

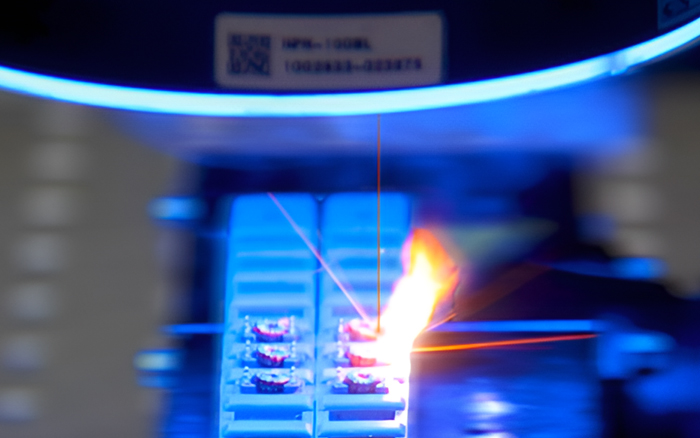

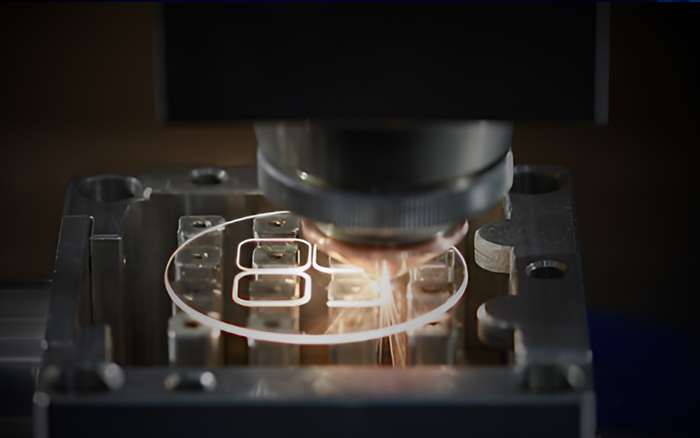

紫外皮秒激光器,全自动切割+裂片工艺,CCD视觉定位与自动对焦。

UV picosecond laser, fully automatic cutting + breaking process, CCD vision positioning and auto-focus.

- 无微裂纹:切割边缘崩边<10μm,保持玻璃高强度

- 高精度异形切割:可加工2.5D/3D曲面玻璃,轮廓精度±0.03mm

- 高良率:自动化洁净生产,良率>98.5%

- No Micro-cracks: Cutting edge chipping <10μm, maintains high glass strength

- High-precision Contour Cutting: Processes 2.5D/3D curved glass, contour accuracy ±0.03mm

- High Yield: Automated clean production, yield >98.5%