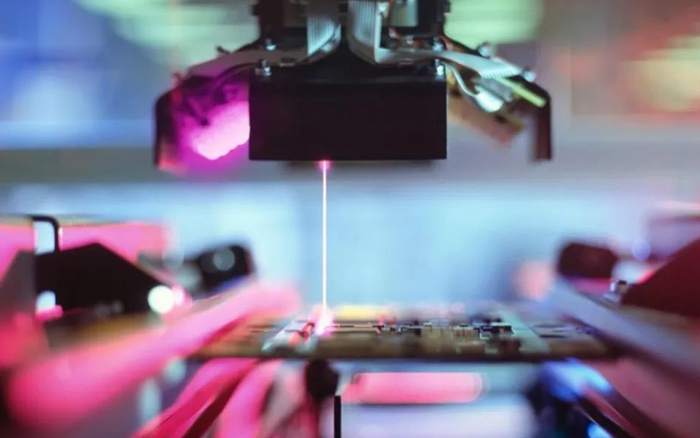

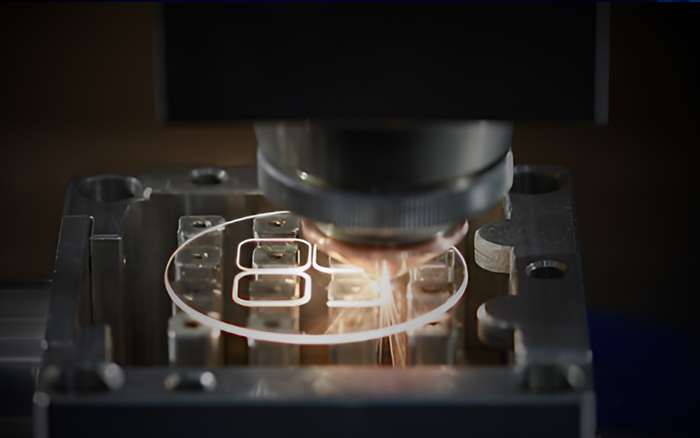

精密螺丝/紧固件激光打标

Precision Screw/Fastener Laser Marking

在不锈钢、钛合金等螺丝表面进行永久性标识,包括规格、批次、二维码等。

Permanent marking on screws (stainless steel, titanium, etc.) including specifications, batch numbers, QR codes.

核心技术要点

Core Technical Points

光纤激光器(20-50W),高精度振镜,旋转夹具,高对比度打标工艺。

Fiber laser (20-50W), high-precision galvanometer, rotary fixture, high-contrast marking process.

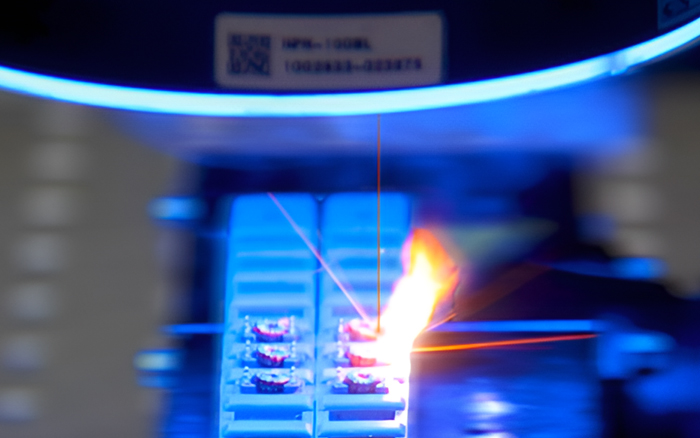

- 永久防锈:标记深度可控,耐腐蚀,不破坏表面防锈层

- 高速高效:单个螺丝打标时间<2秒,适配自动供料系统

- 高识别率:二维码/条形码识别率>99.9%

- Permanent & Rust-proof: Controlled marking depth, corrosion-resistant, no damage to anti-rust layer

- High Speed & Efficiency: Marking time <2 sec per screw, compatible with auto-feeding systems

- High Readability: QR code/barcode readability >99.9%